Quality, precision and reliability are our strenghts!

MegaPlast GmbH

Your excellent partner for:

- 1K and 2K precision injection molding

- Mould construction (pre-series tools also possible)

- Assembly and component production

- Measurement of components

- Prototyping

Prototyping

- Development of plastic parts according to customer requirements

- Assembly and manufacturing of complete assembly groups

- Tampon / silk screen printing , bonding, ultrasonic and thermal welding

- EMC solutions in plastic itself by plating (for example Sn)

- Plate goods, cutting , shaped and contoured, PMMA , PC, ABS , PS and other plastic types

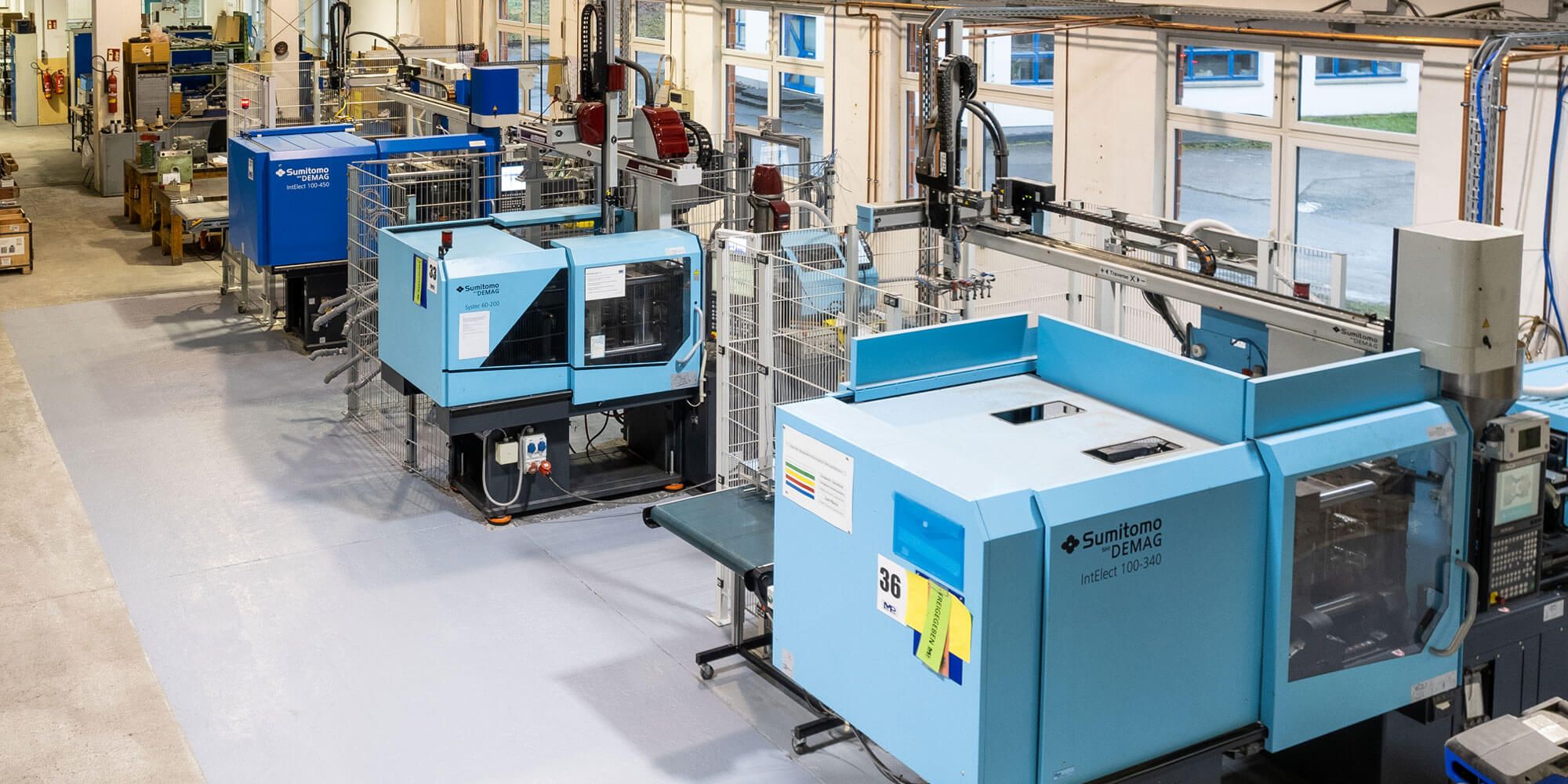

Injection Molding

We manufacture for you in 1 and 2 component technology on 38 machines.

ARBURG and DEMAG machines with clamping forces from 25 t to 350 t are available to meet customer requirements. Furthermore, we have a competent partner at our side to cover clamping forces of up to 1600 t.

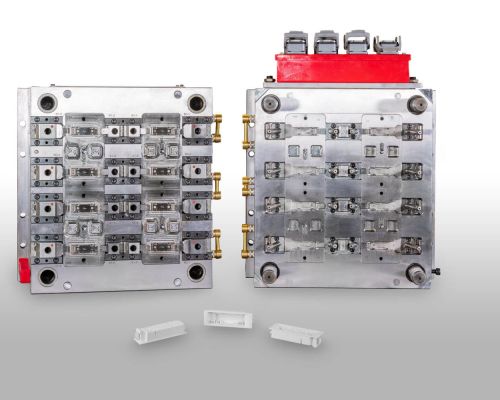

The handling of stack and multifunctional tools and their careful care is constant practice and therefore a precondition for plastic components of the highest quality.

Our Tool Construction

Our tool construction department has capable machinery that we use to manufacture injection moulded tools of aluminium and steel.

The high quality of an injection moulded tool is the absolute top priority to guarantee proper, high quality injection moulding.

We obtain this quality thanks to experience, know-how and modern machines:

- 5 DMU milling machines

- HSC milling machines

- DMU monoBLOCK 650 (5-axis)

- Conventional lathes, milling machines

- Grinders and drilling machines

- 1 wire EDM machine

- 1 sinking EDM machine

Our tool construction process is supported by the SOLIDWORKS/SOLIDCAM CAD/CAM program.